ENGINEERING

& PROGRAMMING

At B&B Manufacturing, we offer more than just advanced metal fabrication services.

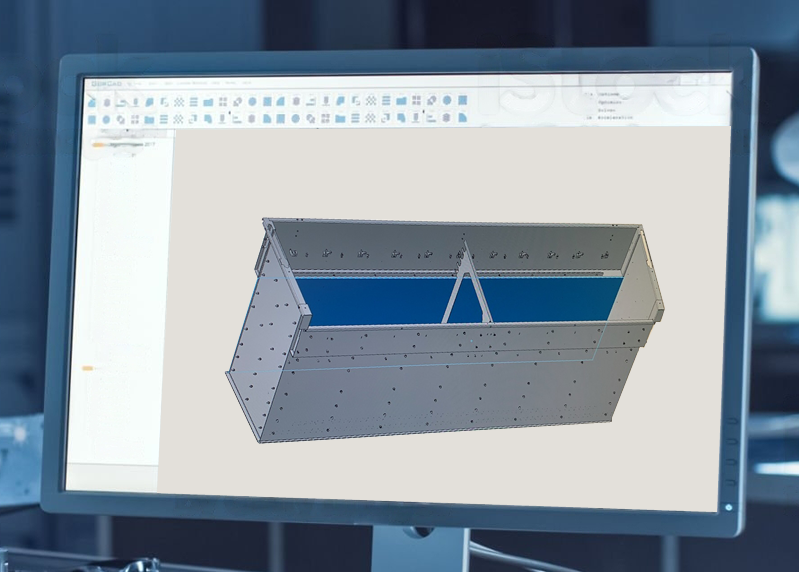

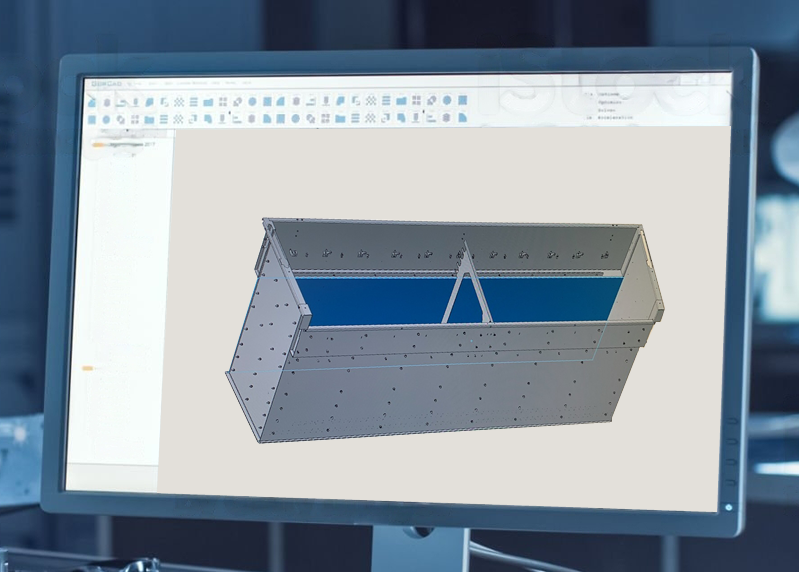

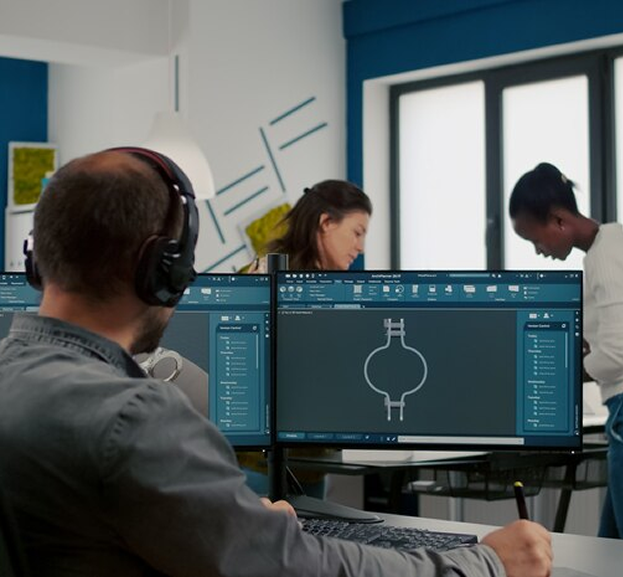

For over 35 years, B&B Manufacturing’s engineering and programming services have been solicited by numerous companies and corporations. We utilize the latest versions of advanced software, including AutoCAD, Solidworks, Sheetworks, and AP100US, to develop accurate 3D models for design and analysis purposes.

Our diverse inventory of software applications gives us the ability to work with a wide range of file types, including .dxf, .stp, .X_T, and .sldprt among others. These programs are directly integrated with our fleet of fabrication equipment, allowing us to transition from engineering to production quickly. For projects without existing CAD files, we can reverse engineer an existing part to fabricate it.

At B&B Manufacturing, we also offer a full range of fabrication services, including laser cutting, bending/forming, MIG/TIG welding, hardware installation, & drilling/machining. We regularly work with an assortment of materials, such as aluminum, carbon, steel, stainless steel, and copper. These offerings, together with our engineering services, let us provide one-stop fabrication solutions for our clients. This simplifies their supply chain, resulting in faster lead times, greater quality control, & significant cost savings.

We understand that time is money, so we work tirelessly to get products into your hands as quickly as possible. We can program, fabricate, inspect, and approve templates within a week of receiving samples. Our strict quality management processes and procedures allow us to meet any client demand without sacrificing quality.

Are you interested in working with B&B Manufacturing for your next metal fabrication project? Contact us to learn more about our services and how they can benefit your operation.

Metal plays a pivotal role in the production of aircraft structures, engines, and various aerospace systems. From fuselage panels and wing components to turbine blades and landing gear, metal parts provide strength, lightweight properties, and withstand extreme conditions encountered in aerospace applications.

From tractor parts and harvesting implements to irrigation systems and livestock handling equipment, metal parts provide durability, strength, and precision in agricultural operations.

Chemical manufacturing for metal parts is a crucial process that involves the application of various chemical techniques and treatments to enhance the properties and performance of metal components.

Electronic manufacturing incorporates metal parts into electronic devices, enhancing their functionality and durability. From circuit boards to heat sinks, metal components provide structural support, electrical conductivity, and efficient heat dissipation.

Food manufacturing relies on metal parts to ensure efficient and hygienic processes. Metal components are integral in food processing equipment, packaging machinery, and conveyor systems. These parts are designed to meet strict sanitary standards, withstand harsh cleaning processes, and maintain food safety.

Machinery manufacturing heavily relies on metal parts to construct robust and functional equipment. Metal components serve as the building blocks of machinery, providing structural integrity, mechanical strength, and reliable performance.

Metal plays a critical role in the construction of marine vessels, offshore structures, and maritime equipment. From hulls and propellers to navigation systems and rigging hardware, metal parts are essential for ensuring seaworthiness, durability, and performance in challenging marine environments.

Military manufacturing heavily relies on metal parts to produce essential components for defense and security purposes. Metal plays a vital role in the construction of military vehicles, aircraft, weapons, and equipment. From armored hulls and bulletproof vests to weapon barrels and aircraft fuselages, metal parts provide strength, protection, and functionality in demanding military operations.

Metal plays a crucial role in the construction of solar panels, mounting structures, and support frames. From aluminum frames and stainless steel fasteners to copper connectors and busbars, metal parts provide durability, stability, and electrical conductivity in solar installations.

Metal components play a crucial role in the production, exploration, and extraction of oil and gas resources. From drilling equipment and wellheads to pipelines and storage tanks, metal parts provide strength, corrosion resistance, and reliability in harsh and challenging oil field environments.

Metal plays a key role in the construction of optical devices such as cameras, telescopes, microscopes, and laser systems. From lens mounts and precision frames to reflective coatings and adjustable mechanisms, metal parts provide stability, precision, and durability in optical instruments.

Metal plays a crucial role in the construction of packaging machinery, containers, and closures. From metal cans and jars to caps and lids, metal parts provide durability, security, and preservation for a wide range of products.

Let us help make your life easier with our awesome support and service. We won't leave you hanging, and keep you updated at all times.

Everything we create and build is done right here in our Maryland headquarters. Trust only the best quality and workmanship here in the good ole' USA.

Every single part we create adheres to the highest quality standards. Every part we ship faces the toughest scrutiny before leaving our warehouse.

Trust that anything you have us create for you is secure, safe and confidential. From start to finish, we ensure the highest standards are met for your product requirement.