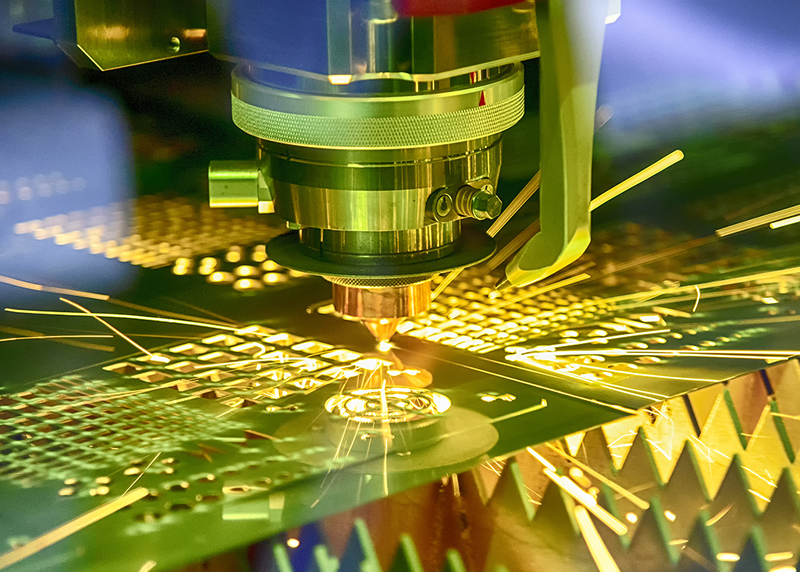

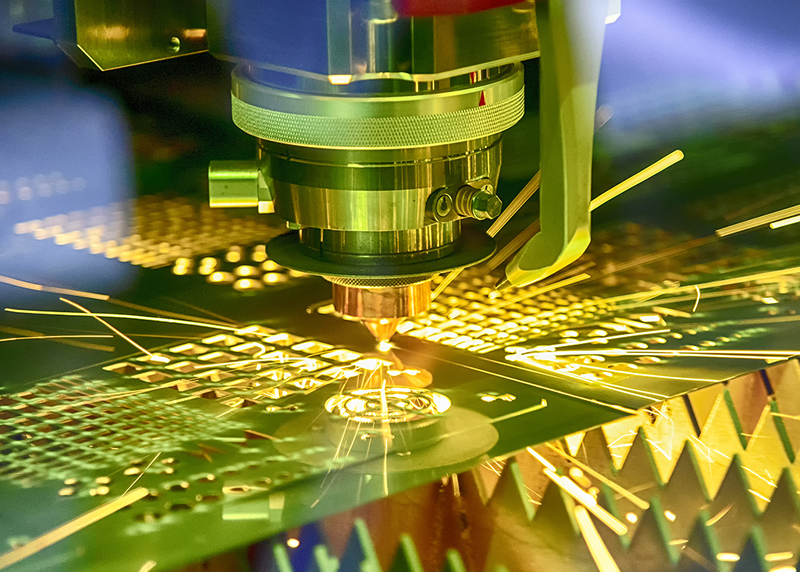

ULTRA-PRECISE

LASER CUTTING

At B&B Manufacturing, we use high powered lasers to create incredibly accurate cuts on materials such as 6061 Aluminum, Mild Steel, and Stainless Steel.

At B&B Manufacturing, we use high powered lasers to create incredibly accurate cuts on materials such as 6061 Aluminum, Mild Steel, and Stainless Steel.

Making sure your file meets all our requirements will ensure you get your parts as quickly as possible.

Select your material, apply additional services, and adjust your quantity to see live pricing updates.

3-5 day shipping on all standard orders!

Let us help make your life easier with our awesome support and service. We won't leave you hanging, and keep you updated at all times.

Everything we create and build is done right here in our Maryland headquarters. Trust only the best quality and workmanship here in the good ole' USA.

Every single part we create adheres to the highest quality standards. Every part we ship faces the toughest scrutiny before leaving our warehouse.

Trust that anything you have us create for you is secure, safe and confidential. From start to finish, we ensure the highest standards are met for your product requirement.